-

Address

Address -

Mail Us Oninfo@mamtatools.in

Mail Us Oninfo@mamtatools.in

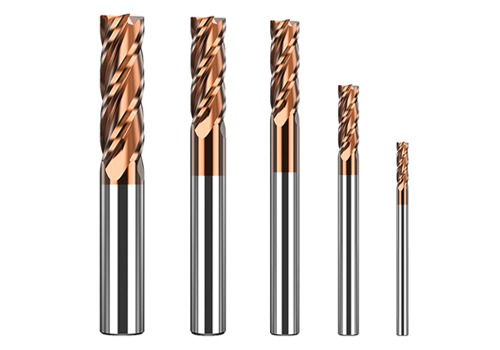

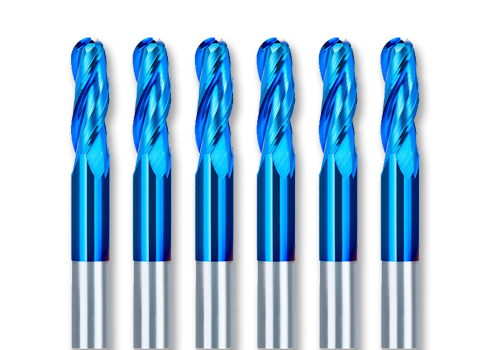

We are supplier of 45,55,65 HRC endmill & Ballnose and our setup is situated in Talawade, Pune, Maharashtra, India.

End mills and ball nose cutters are essential tools in machining, each serving distinct purposes in the milling process. End mills feature cutting edges at the tip and sides, allowing for a variety of milling operations such as slotting, profiling, and contouring. They come in various shapes and sizes, offering versatility for different applications and materials. On the other hand, ball nose cutters have a rounded end, resembling a ball. This design allows for smoother contouring and 3D profiling, making them ideal for creating curved surfaces and intricate shapes. Ball nose cutters are particularly valuable in sculpting and finishing operations, where a finer surface finish is desired. Both end mills and ball nose cutters can be used for roughing and finishing, contributing to the precision and efficiency of milling processes across industries like manufacturing, aerospace, and mold-making. Their diverse applications and configurations make them indispensable tools for machinists seeking optimal results in shaping and sculpting various materials with accuracy and finesse.

- High Material Removal Rate

- Versatility

- Surface Finish

- Cost-Efficiency

- Consistency

- Reduced Vibration

- High Feed Rates

- Suitable for Various Materials

- Accessibility

- Adaptability

- Safety